Weather pack connectors are popular types of terminals/connectors, especially in the automotive industry, heavy-duty machinery, and marine applications. One distinguishing feature is their ability to withstand extreme moisture, temperature, and mechanical stress, thus making them appropriate for such applications. Overall, weather pack connectors/terminals make pretty reliable connections.

One of the most reliable methods of making weather pack connections is crimping. This post is a step-by-step guide to crimping weather pack connectors/terminal pins. Therefore, you can easily make reliable and weather-resistant electrical connections.

Tools and Material Needed

1. Weather pack connector kit

Ensure you have a weather pack connector kit with male and female terminals. More importantly, your chosen kit should be ideal for your application. Consider the iCrimp WP-404 Weather Pack Connector Kit.

2. Wire

Choose a wire with a gauge that matches your connectors.

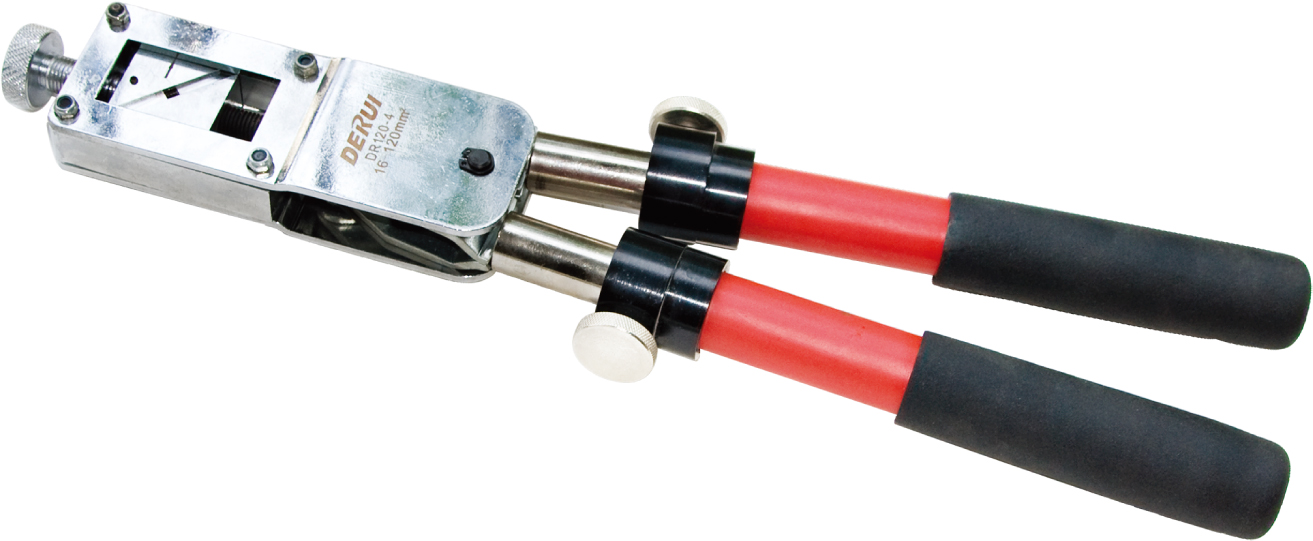

3. Crimping tool

When choosing a crimping tool, you need to consider the barrel style on the terminals. For terminals with an open barrel, choose a B-type crimp tool like the iCrimp IWC-1424AB crimping tool. For a closed barrel, choose an F-type crimp tool.

4. Wire cutter

A wire cutter is quite helpful in wire preparation, precisely cutting the wire to the desired length. A good wire cutter should give you smooth and neat cutting.

5. Wire stripper

It strips off the insulation on the ends of a wire where the terminal is inserted.

6. Wire seals

It provides extra protection on the crimped connection. Some weather pack connector kits come with wire seals. Above all, ensure the seals are correctly sized.